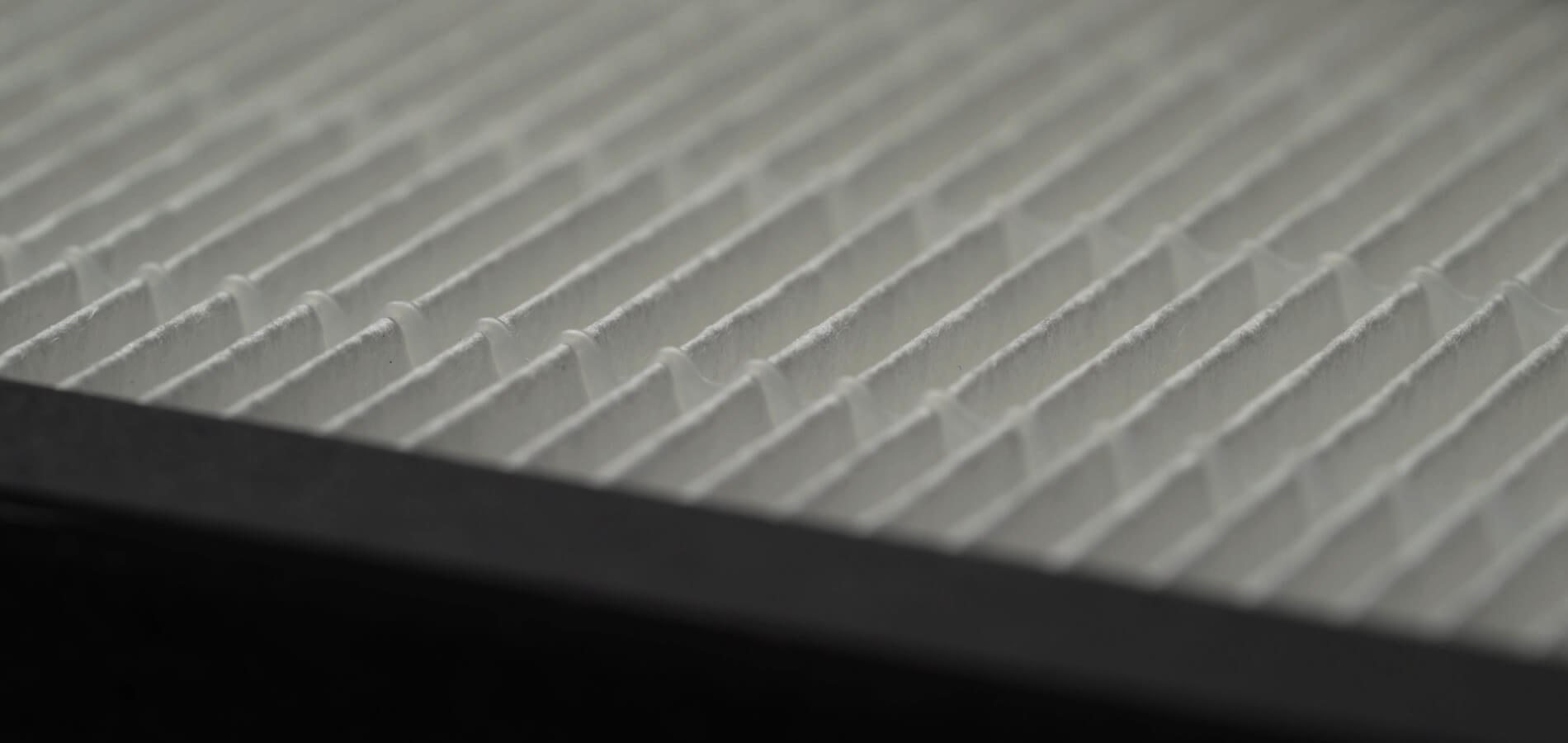

For over 40 years, JAS Filtration has excelled in providing commercial, industrial, and institutional filtration solutions. We conduct precise and in-depth diagnostics, applying integrated, innovative, and proven solutions—ranging from general ventilation to specialized projects.

With a comprehensive approach and high-quality products, JAS Filtration offers solutions that reduce total filtration costs. This is achieved through the installation of filters with greater particle retention capacity and lower resistance profiles throughout the filter’s lifespan, ultimately minimizing filter change frequency.