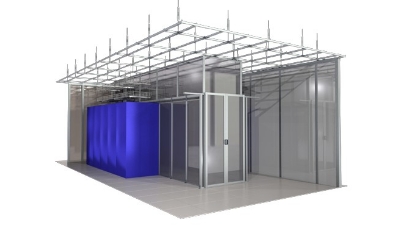

Depuis plus de 40 ans, JAS Filtration excelle dans les solutions de filtration commerciales, industrielles et institutionnelles, en posant des diagnostics justes et élaborés auxquels s’appliquent des solutions intégrées, innovantes et éprouvées, de la ventilation générale et des projets spéciaux.

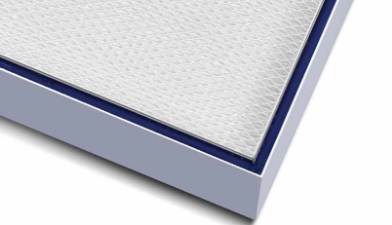

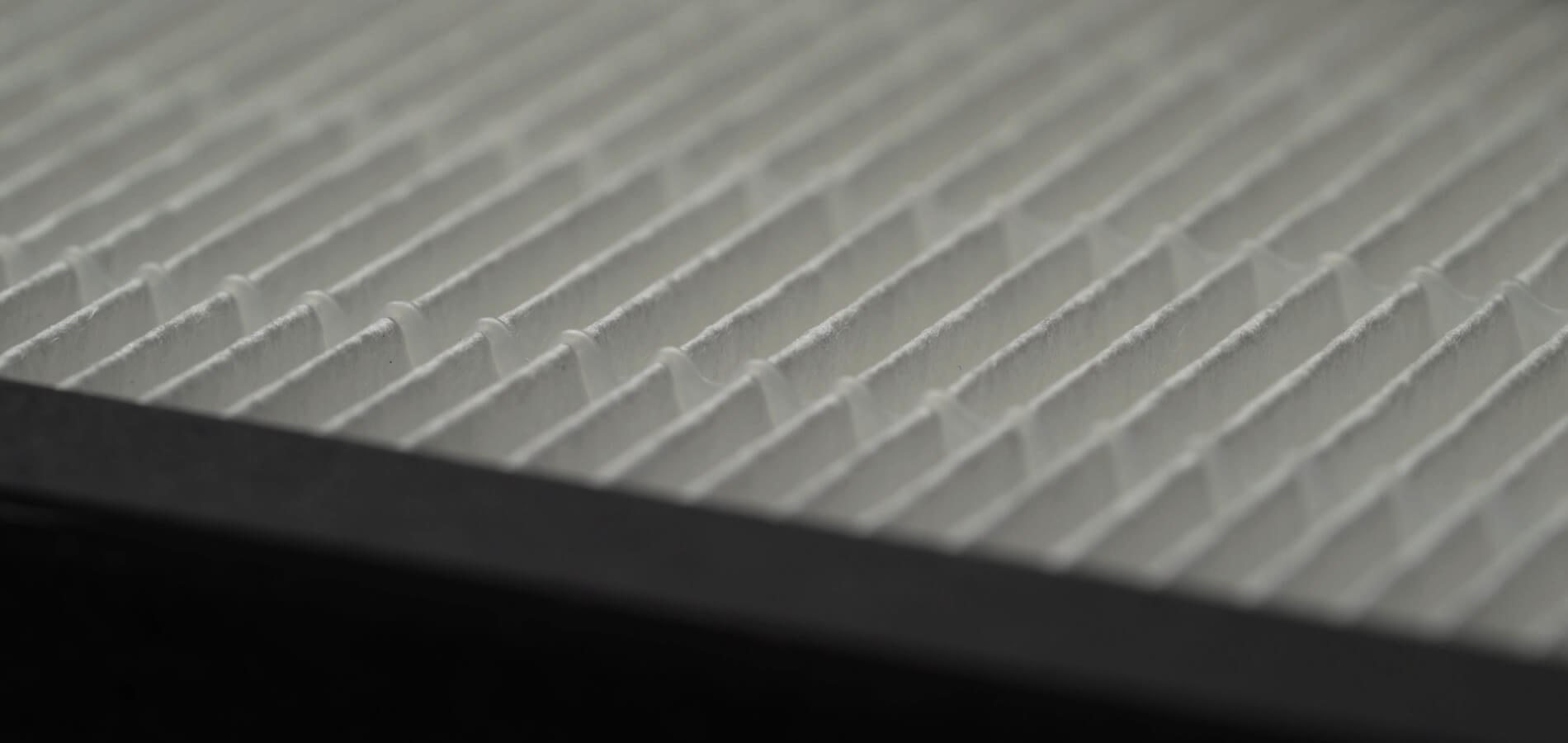

En misant sur une approche globale et des produits de haute qualité, JAS Filtration offre des solutions permettant une réduction des coûts totaux liés à la filtration. Ceci est entre autres possible grâce à l’installation de filtres offrant une plus grande capacité de rétention des particules et un profil de résistance plus faible tout au long de la vie du filtre, limitant ainsi le nombre de changements de filtres.